| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

Preferred Buyer From

| Location | Worldwide |

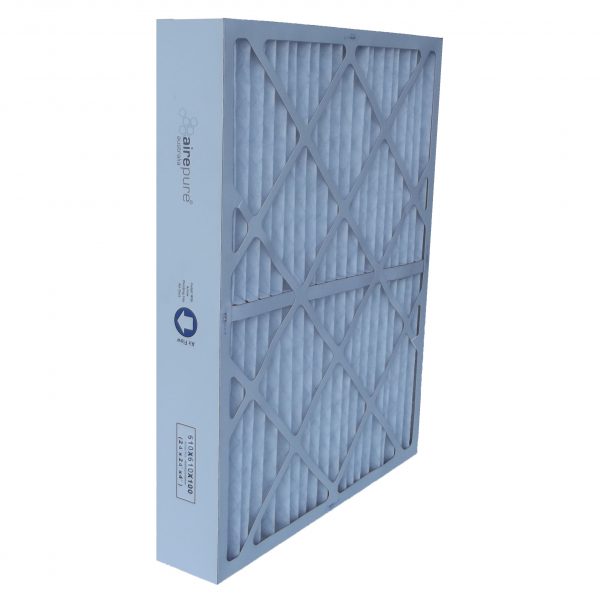

CLEANROOM Filters MANUFACTURER INDIA

For

- Hospital Environment

- Pharamaceuticals companies.

- Clean Rooms for industry

- Beverage industry

- Hotels

- Malls, Cinema house and Commercial Office complex

Air Filtration and its Practical Application

The essential functions of HEPA Filters are to improve indoor Air Quality and to protect downstream equipments and facility components. Good HEPA Filters controls all human sneeze droplets.

HEPA FILTER Filtration Mechanisms

The two main streams of filtration employed by HEPA filters are

- Particulate filtration typically uses a randomly arranged mesh of fibers to capture small particles via the methods of impaction, interception and diffusion. In a simplistic way, particulate filtration relies on the probability that as a particle passes through these fibres in the direction of bulk airflow.

- Gaseous filtration methods commonly used by HEPA filters are adsorption or chemisorption. Activated carbon media, which consist of micro-pores within larger granules, use the adsorption method. Small gas molecules find their way inside these pores where various forces adsorb the gas molecules to the media and hold them there, therefore removing them from the airstream (like a sponge adsorbing water). Chemical infused media such as potassium permanganate use the chemisorption method –whereby small gas molecules find their way inside these pores and are molecularly changed by chemical reaction when they contact the media. This chemical reaction permanently converts odourous/toxic gas molecules into a harmless salts and gases.

HEPA Filter Performance

There are several aspects of HEPA filter design that impact on filtration performance. The important parameters include:

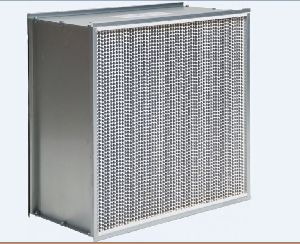

- Material / Type: Different media types can have various effects on efficiency. Synthetic filter media are resistant to moisture build up and ideal for preventing the proliferation of mould and mildew. Glass fibre is typically a finer filter media, more tolerant of chemicals and high temperatures, but can be quite fragile.

- Thickness / Density : Thicker or denser filter media have higher filtration efficiency and higher pressure drop. Deeper, graduated filter medias can hold more contaminants, than thin media grades.

- Fibre Quality / Size : Quality air media lasts longer and does not shred fibres in the duct. Fibre size can have various effects on efficiency.

- Surface Area : Higher media surface area equates to a lower pressure drop and higher contaminant holding capacity. Pleated air filtration media has a greater surface area and contaminant holding capacity than flat air filtration media. The higher the number of pleats, the larger the surface area it can contain. Ultimately, the higher surface area maximises the filtration and contaminant holding capability and reduces energy consumption

HEPA Filters standards

Globally accepted HEPA Filter performance rating systems are

- EN779:2012 (G1 to F9),

- EN1822:2009 (E10 to U17),

- ASHRAE 52.2 (MERV 1 to 16)

- ISO16890 (ISO coarse to ISO ePM1).

Looking for "Clean Room Filters" ?

Piece